ALIGNMENT

The Self-Clinching Advantage

Modern designers and engineers have a nearly limitless selection of bearing types and configurations from which to choose. With so many options, why should you consider Spyraflo? The answer is simple. Our self-clinching capability just might change the way you design your products.

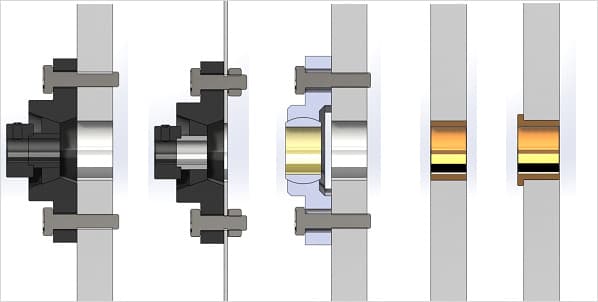

During installation, self-clinching splines displace the mount material into the retainer groove creating a retention ring from the host metal. The splines prevent rotation after installation, and motion only takes place where intended by design. Self-clinching bearings install in mere seconds, becoming a permanent part of the mount, flange, panel, bracket or other component into which they are installed. They are very compact and don’t require additional fasteners.

Self-clinching gives designers the exceptional ability to clinch into thin sections such as sheet metal or die castings. Self-clinching requires a minimum mount thickness, but there is no limit on how thick the mount can be.

Using self-clinching Spyraflo bearings is the most efficient means of permanently mounting bearings for shaft sizes of .093 to 1.250” [2mm to 30mm]. Available in both plain and rolling-element bearing types, self-clinching bearings are a dream come true for products designed using Design for Manufacture and Assembly (DFMA ) principles. Primary DFMA objectives are met by:

- Reducing number of parts

- Simplifying assembly operations

- Decreasing production time

- Increasing productivity and efficiency

- Reducing material usage and cost

- Minimizing overall system/product cost

- Relaxing manufacturing tolerances

- Adapting to component variability

- Improving product quality/reliability

- Eliminating post-assembly adjustments

- Promoting modular design

- Efficiently using available space

Typical mounted bearings require fasteners and additional assembly labor. Straight bushings require thicker mounts and are not adaptive to component tolerances. Where precision is required, bushings must be machined or fitted after installation because the bore closes after being pressed into place.

Figure 2. Improperly loaded ball bearings have shorter service life

Spyraflo self-clinching bearings are automatically located during installation into a die-casting, laser-cut sheet, stamping or other metal component. Spyraflo self-clinching bearings are self-adaptive and compensate for process variations and tolerances, and provide a bearing bore unaffected by the installation process. Save space, time and resources while improving your products with Spyraflo self-clinching bearings.

We offer bearings in press-fit, self-clinching, or mounted configurations, with plain or rolling elements, in a variety of materials. Bearings come in standard inch and metric sizes — including miniature options.

© 2026 Spyraflo Bearings. All Rights Reserved.